How To Put Insulation In The Ceiling

This department provides a guide on "how to install insulation." It covers specific data on installation details for attics and ceilings that will assist with proper installation to encounter RESNET Grade 1 criteria for fiberglass and mineral wool batt insulation. Covers topics from hatches to ventilation baffles, and provides links to publications and videos for more data.

Click Here to download a PDF of these instructions in English language

Click Here to download a PDF of these instructions in Spanish

Critical Details for Ceiling and Attic Batt Insulation Installation

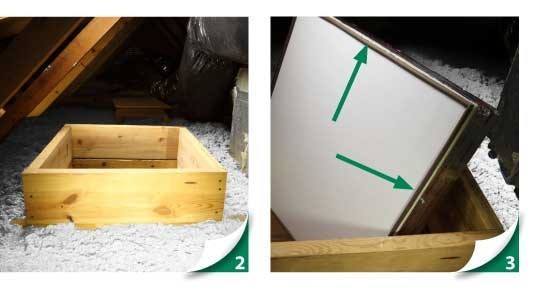

Attic Admission Hatches – Seal and Insulate for Best Installation Results

– +

Insulation Options

Choice 1A: Permanently attach batt insulation to the attic admission. Ensure that R-value meets or exceeds surrounding insulation levels.

Pick 1B: Permanently attach rigid insulation to the attic access. Ensure that R-value meets or exceeds surrounding insulation levels.

Disquisitional Details

- Install dams around access holes to protect the surrounding insulation.

- Install atmospheric condition-stripping on access trim. Verify seal.

Notes:

When insulating pull-downward stairs, pre-fab or site-built, insulated and weather-stripped covers are recommended.

At that place are multiple options for attaching insulation to the access hatch. The intent is for the insulation to remain fastened after repeated homeowner use and that the insulation has an equivalent R-value of the surrounding attic insulation.

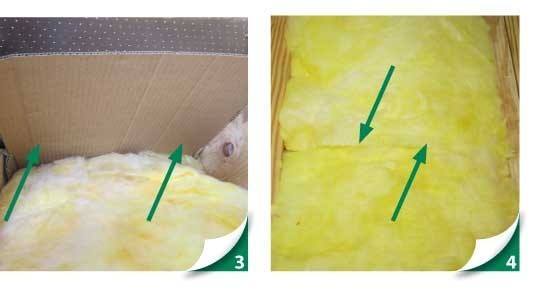

How to Install Batt Insulation in Ceilings with Attics

– +

Disquisitional Details

- Verify insulation textile is the right width and R-value for the location.

- Friction fit insulation snugly between and parallel to all standard and narrow attic framing members.

- Ensure insulation extends to the outside edge of the exterior height plates and is flush against whatsoever ventilation dams/baffles.

- Ensure ends of insulation are butted together and flush to underside of framing.

- When using kraft-faced batts: Fasten kraft face up tabs of insulation to the underside of framing members. Notation: No kraft paper overlapping required.

- When using vapor retarder and unfaced batts: Fasten vapor retarder to underside of framing once batts are installed. Overlap seams at to the lowest degree 2 inches.

- In the attic, install a card that indicates attic insulation levels in the firm to meet code requirements.

Options

- Selection: When installing multiple layers of insulation for optimal thermal performance, install the starting time layer (bottom layer) parallel to attic framing members and affluent with both bottom and top. Install the second layer (pinnacle layer) perpendicular to cranium framing members. Both layers combined must equal at least the required R-value.

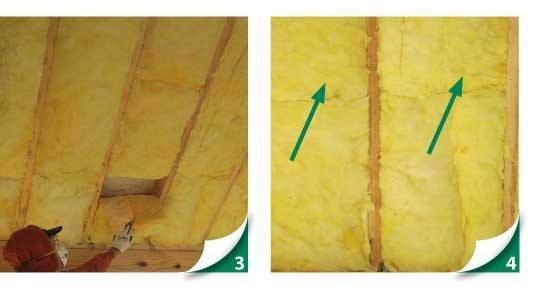

Batt Insulation Installation Techniques – Ceilings without Attics (Unvented)

– +

Critical Details

- Verify insulation material is the correct width and R-value for the location.

- Friction fit insulation between and parallel to the attic framing members.

- Ensure insulation extends to the exterior edge of the exterior top plates and to the peak of the cathedral ceiling.

- Ensure ends of insulation are butted together and affluent to underside of framing.

- When using kraft-faced batts: Spike kraft confront tabs of insulation to the underside of framing members. Note: no kraft paper overlapping required.

- When using vapor retarder with unfaced batts: Spike vapor retarder to underside of framing members one time batts are installed.

Batt Insulation Installation – Ceilings without Attics (Vented)

– +

Critical Details

- Verify attic insulation material is the correct width and R-value, and ventilation chutes and baffles have been installed per manufacturers' specs.

- Friction fit insulation betwixt and parallel to the attic framing members.

- Ensure insulation extends to the outside edge of the exterior top plates and is flush against all ventilation dams and bamboozle boards.

- Ensure ends of insulation are butted together and flush to underside of framing.

- When using kraft-faced batts: Fasten kraft face tabs of insulation to the underside of framing members. Note: No kraft paper overlapping required.

- When using vapor retarder with unfaced batts: Fasten vapor retarder to underside of framing members once batts are installed.

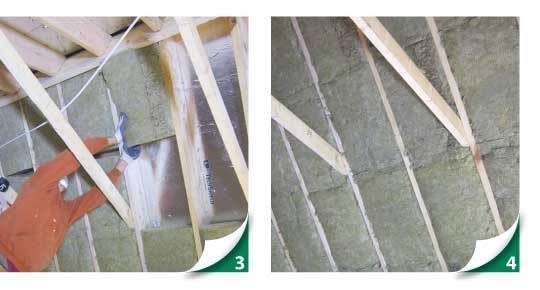

Batt Insulation Installation to Roof Deck – Conditioned Attics

– +

Critical Details

- Verify insulation material is the correct width and R-value for location. Too, verify the depth of roof rafters is at least the depth of the required R-value.

- Friction fit insulation between and parallel to the attic framing members.

- Ensure attic insulation extends to the outside edge of the exterior elevation plates and to the peak of the cathedral ceiling.

- Ensure ends of attic insulation are butted together and flush to underside of framing.

Note: Ensure conditioned attic insulation strategy is compliant with local fire codes.

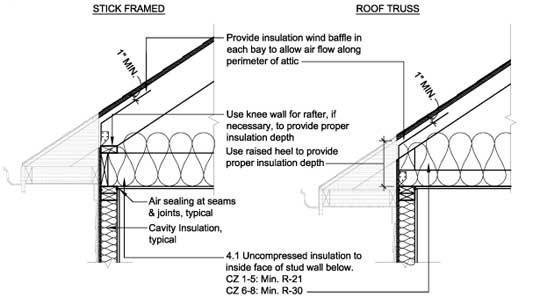

Ventilation Baffles for Insulation Installation – Ceilings with Attics

– +

Critical Details

- Verify that space between roof deck and top plate will arrange the appropriate insulation and a minimum ane-inch of required air space.

- Mensurate and mark the height on the baffle. Verify the height allows for 1-inch of required air space.

- Cutting side fin and fold bamboozle at the measured marker to allow for correct insulation pinnacle.

- For all eaves with vents, spike bottom of baffle in identify to allow attic insulation to completely cover the top plate.

- Fasten height portion of baffle in place to allow for a minimum 1-inch space between baffle and roof deck.

- Note: If cathedral ceiling, fasten baffle boards to provide continuous unblocked airflow from soffit vent to ridge vent.

- Notation: Carefully cut bamboozle around any framing obstructions to forestall air movement through insulation.

Ventilations Chutes for Batt Insulation – Ceilings without Attics (Vented)

– +

Critical Details

- Spike baffle board to underside of roof deck extending by the outside edge of the top plate and across the peak of the insulation.

- Measure out and mark the acme on the baffle. Verify the tiptop allows for ane-inch of required air infinite.

- Cut soffit dam material to allow for correct insulation height and whatever obstructions.

- For all eaves with vents, spike soffit dam cloth to the attic framing or permanent blocking and then that insulation will completely cover the top plate.

- Annotation: If cathedral ceiling, spike bamboozle boards to provide continuous unblocked airflow from soffit vent to ridge vent.

Notes:

- For ceilings with attics, it is only necessary to install ventilation baffles. For ceilings without attics (vented), install both ventilation baffles and chutes.

- Ventilation chutes should be installed with a 2" gap betwixt the ends. Reduce gap to ½ " when using blown-in insulation.

Options

Technical Tips for Ceiling and Cranium Batt Insulation Installation

Obstructions/ Obstacles

– +

Boxes (electrical, smoke, CO, etc.)

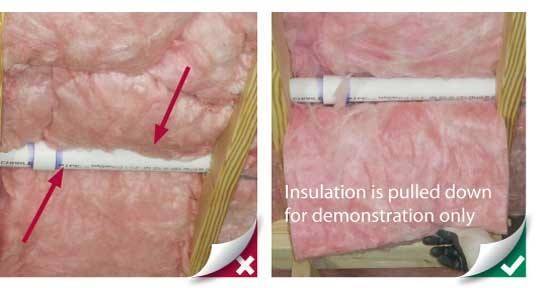

Do: Cutting and/or split insulation around wiring and boxes.

Ceiling Fan Boxes

Do: Cutting and/or split insulation around wiring and boxes.

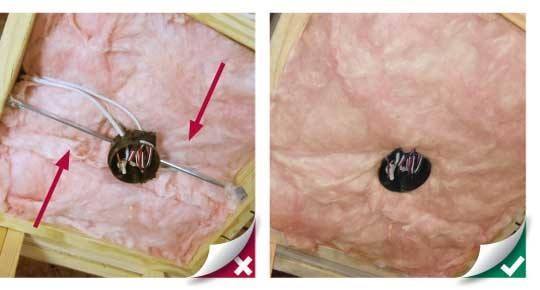

Recessed Lights (IC and ICAT rated simply)

Do: Cut and/or split insulation around wiring and recessed lights and fit snugly to boxes. Notice: Recommend using ICAT rated.

Wires (electrical, cable, security, low voltage, etc.)

Practice: Cutting and/or split insulation around wiring and fit snugly to boxes and other obstructions.

Frazzle/Ventilation Fans

Practice: Cutting and/or split insulation effectually exhaust fan boxes, ductwork, wiring and any support bracing and fit snugly to boxes.

Ducts/Connectors

Exercise: Cut and/or divide insulation around HVAC Boots and insulated ductwork and any back up bracing.

Pipes (Water Supply, Plumbing Vents, etc.)

Do: Cut and/or carve up insulation around pipes

Notes:

The clearance between insulation and fossil-fuel appliances, chimneys, recessed lights and other hot surfaces must meet the requirements of the National Burn Protection Association (NFPA) and International Code Council (ICC) building codes, and the apparatus manufacturers' recommendations – whichever is most restrictive.

In full general, when installing insulation in contact with or near hot surfaces:

- Cheque the manufacturer'south instructions for equipment and appliances to make up one's mind whatever insulation requirements or restrictions.

- Cheque the applicable building lawmaking for insulation clearance requirements. These are typically contained in the fire, building and mechanical codes. If in that location are whatsoever questions – consult your local building department for the applicable requirements.

- Mineral cobweb insulation (fiberglass, rock and slag wool) are noncombustible but may take flammable facings which cannot exist used in hot applications. These insulations are also available with noncombustible facings and facings which have flame spread and smoke developed indices advisable for most code requirements.

- When it is permissible to insulate in hot applications, note that most fiberglass products used in edifice insulation melt at approximately 800 degrees F and rock wool products used to insulate buildings melt at approximately 1200 degrees F. Both fiberglass and rock wool materials are available which have higher melting temperatures.

How To Put Insulation In The Ceiling,

Source: https://insulationinstitute.org/im-a-building-or-facility-professional/residential/installation-guidance-2/attics-and-ceilings-2/

Posted by: vallejopostra.blogspot.com

0 Response to "How To Put Insulation In The Ceiling"

Post a Comment